Drone-Mounted Thermal Imaging

How does thermal imaging detect a problem?

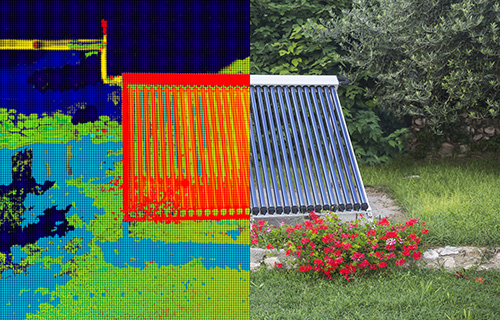

Over time solar panels may reduce their output through the development of defects, dirt build up and on occasion accidental or malicious damage which can cause a severe drop in efficiency. The majority of the time these defects will be invisible to the naked eye and when they are visible, they can take excessively long periods of time to find. A thermal imaging camera detects the heat given off an object and will immediately highlight any variable temperatures in the cells of the solar panels. If parts of the solar panel are hotter than others, it usually indicates a fault.

Viridian UK can provide drone mounted thermal imaging from a fully licensed and insured drone mounted camera system, flown by a fully qualified pilot licensed by the CAA. This enables us to carry out large area solar PV surveys across multi-acre ground mounted installations and on hard to access building roofs.

Solar Panel Maintenance by Thermal Imaging

Solar PV panels convert energy from the sun and following installation, provide a free source of electricity. However, in order to ensure that any installed solar PV panels are maintaining their efficiency, it is important to carry out regular monitoring to ensure that they are generating effectively. They can highlight anomalies and ineffectiveness in a solar panel, so it is possible to resolve a potential problem before it becomes a major issue.

For more information, Contact Us.

Thermal imaging can be used to carry out a full assessment of the solar cells in each of your PV panels whilst your solar panels are installed, this can provide quality assurance immediately after an installation is complete and highlight any potential future issues. The survey takes place during daylight working hours with minimal disruption.

The Benefits of Thermal Imaging

An unmanned aerial drone can fly quickly across vast areas mapping the various faults in a solar PV array, identifying which panels have broken down and which ones are going to break down. Once identified, these defective panels can be swiftly dealt with and replaced to ensure that the array continues to maximise its output. The costs of using the drone can be many times less than that of a manual survey which will require the individual testing of every panel along a string in an array that is performing poorly. For example, array strings can be many hundreds of panels. If it took a person 10 minutes to test each panel in a string of say 100 panels, it would take them approx 17 hours to find the fault – that’s 17 hours of a highly paid electrician if they can work at super quick rates to find the fault (if it can be identified). Thermal imaging could find the faulty one in the air within 10 minutes.

Monitoring and Maintenance

- Thermal imagery

- Drone thermal imagery

- Comprehensive panel degradation reports

- Monitoring suite